-

- Shandong Daqiao Co., Limited.

- Tel: +86 532 85719155/85719176

- Fax:+86 532 85719186

- Add:Room 105, Block 3,No.20 West of Yinchuan road, Qingdao, China

- E-mail:info@daqiaorefractory.com

wenqin@daqiaoindustry.com - Manufactory: Shandong Daqiao Refractory Plant / ShanDong Luqiao New Material CORP.

- Add: West of Renmin Road, Boshan, Zibo, Shandong, China / Luqiao Road, New Material Industry Area, Boshan Economic Development Zone, Zibo, Shandong, China

-

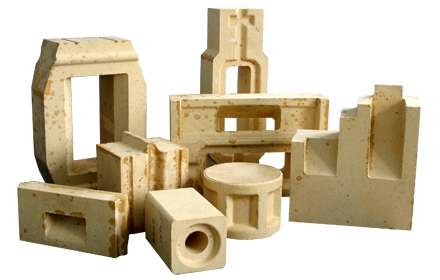

Silica brick for coke oven

材质(Grades) 检验标准

Inspection

StandardKN KD KS 典型砌筑部位 Model Build Part 高温操作碳化室

High Temperature Handle Coking Chamber炉墙、炉顶、蓄热室和正面

Oven Wall、Oven Top、Regenerator & Front Face化学成分

Chemical analysisSiO2 % µG

σ≥94.5

1.0≥95

1.0DIN51070

Teil26)Al2O3 % µG

σ≤2.0

0.3≤1.5

0.3

DIN51070

Teil36)Fe2O3 % µG

σ≤1.0

0.2≤1.0

0.2DIN51070

Teil56)CaO % µG

σ≤3.0

0.35≤3.0

0.35DIN51070

Teil66)Na2O+K2O % µG

σ≤0.35

0.02≤0.35

0.02DIN51070

Teil86)残余石英

Remnant

Quartz原料类型A (粗晶)

Raw-material

A (Coarse Crystal)% µG

σ

Xmax根据制造厂提供的数据进行协商

Discuss with the Data Offered by Manufactory

6.0【2】 原料类型A (隐晶)

Raw-material

A (Aphanitic Crystal)% Ts

σ1.5

0.5常温耐压强度

Cold crushing strength (KDF)N/mm2µG

σ

Xmax≥28

10

20≥35

10

25≥45

10

30DIN51067

Teil11开口气孔率

Apparent porosity (Po)% µG

σ≤24.5

1.3≤22.0

1.3≤22.0

1.3DIN51056 荷重软化点

Refractoriness under

load(DFB)

开始温度

Starting temperature (ta)oC µG

σ≥1640

25≥1650

25DIN51064 荷重软化点

Refractoriness (DE)

(示差法)T 0.5oC µG

σ根据制造厂提供的数据进行协商

Discuss with the Data Offered by ManufactoryDIN51053

Teil1Z5-25

蠕变Creep (DFI) 3)

Z25% µG

σ

µG≤0.12

0.05-

-DIN51053

Teil2≤0.35

0.1-

-耐火度

Refractoriness 4)µG

σ170(SK31) 5)

2(SK1) 5)-

--

-DIN51063

Teil1波美法磨损度

Baume Abrasion Degreemm µG

σ-

--

-≤4.5

1.0DIN52108

-

| Tel: +86 532 85719155 Fax: +86 532 85719186 Address: Room 105, Block 3,No.20 West of Yinchuan road, Qingdao, China Manufactory : Shandong Daqiao Refractory Plant / ShanDong Luqiao New Material CORP. Phone: +86 533 4290064 Address: West of Renmin Road, Boshan, Zibo, Shandong / Luqiao Road, New Material Industry Area, Boshan Economic Development Zone, Zibo, Shandong |

| Copyright © 2010 SHANDONG DAQIAO REFRACTORY PLANT |